BLOG

-

Perfektní vstřikovací stroje, které nám pomáhají vytvářet nekonečný produkt

možnosti V této části s hrdostí představujeme výjimečné vstřikovací stroje naší společnosti a neomezené možnosti, které přinášejí do výroby vašich produktů.Pokročilá technologie a zajištění kvality: V naší společnosti se naše stroje vyznačují vysoce přesnou ko...Přečtěte si více -

Dvacet běžných materiálů pro vstřikování: Pochopení rozmanitosti světa plastů

materiály Úvod/ oblast použití charakteristika ABS ABS je všestranný materiál pro vstřikování, který kombinuje houževnatost a odolnost proti nárazu polybutadienové pryže s tuhostí a zpracovatelností polystyrenu.Běžně se používá v au...Přečtěte si více -

Proces vstřikování – Šest kroků, které vás seznámí s celým průběhem procesu vstřikování

Co je vstřikování?Vstřikování je výrobní proces, který zahrnuje vstřikování roztaveného plastu do formy a její vychladnutí a ztuhnutí za vzniku konečného produktu.Je široce používán při výrobě různých plastových předmětů, od malých ...Přečtěte si více -

Jak ovládat barvy vstřikování

Vstřikování je oblíbený výrobní proces, který vyrábí širokou škálu plastových výrobků.Barva plastového materiálu je kritickým faktorem, který určuje kvalitu a estetickou přitažlivost konečného produktu.V tomto článku budeme diskutovat o tom, jak vstřikovat...Přečtěte si více -

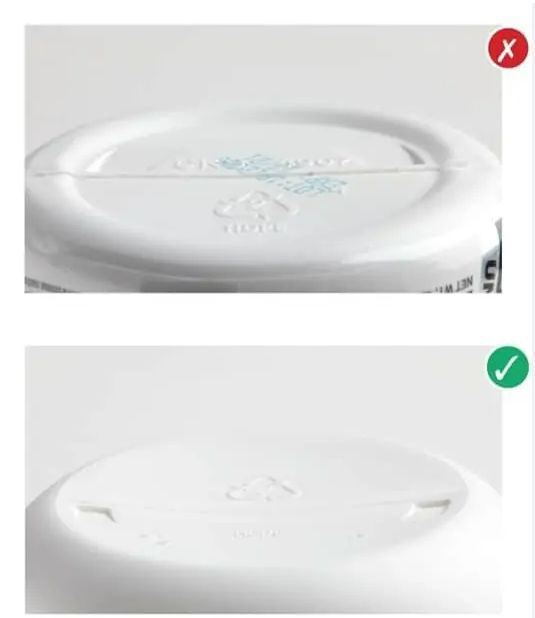

Více o umístění vtoků a vtokových kanálků a toku materiálu

Umístění vtoků a vtokového kanálu je klíčovou součástí procesu vstřikování.Umístění těchto komponentů může ovlivnit kvalitu konečného produktu a také efektivitu procesu.V tomto článku prozkoumáme více o umístěních...Přečtěte si více -

Výběr správného specialisty na vstřikování je rozhodující pro úspěch vašeho projektu

Výběr správného specialisty na vstřikování je rozhodující pro úspěch vašeho projektu.Níže jsou uvedeny některé z klíčových faktorů, které je třeba vzít v úvahu při výběru specialisty na vstřikování: 1. Zkušenosti: Hledejte vstřikování...Přečtěte si více -

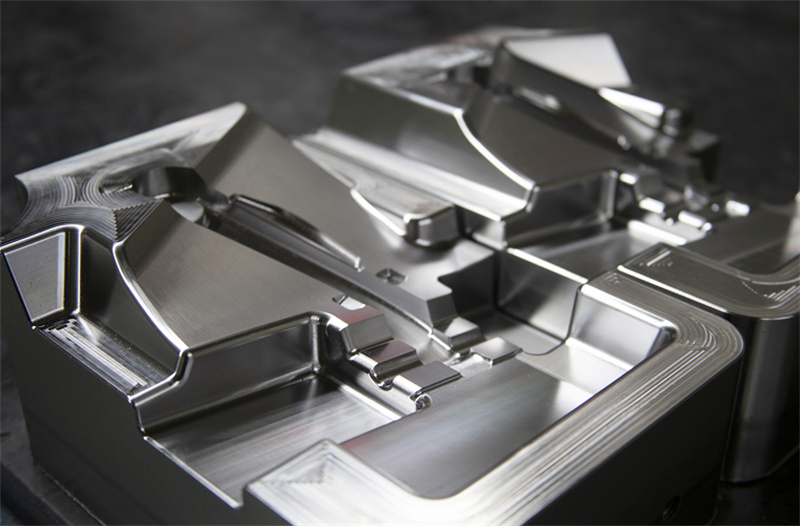

Výběr materiálů pro vaši vlastní plastovou vstřikovací formu

Vzhledem k tomu, že existuje široká škála materiálových možností pro vlastní lisování plastů, je pro produktové inženýry nejužitečnější zaměřit se na primární funkci a pracovní prostředí svých dílů.To umožňuje zúžení správného materiálu pro vaše vlastní vstřikovací...Přečtěte si více -

Opotřebují se plastové vstřikovací formy nebo mají omezenou životnost?

Vstřikovací formy na plasty se mohou opotřebovat v důsledku tření nebo opakovaného kontaktu mezi součástmi během tisíců cyklů.Opotřebení postihuje především brány, šoupátka, vyhazovače a další pohyblivé prvky ve formě.Když komponenty kloužou nebo se dotýkají...Přečtěte si více -

Průvodce designem povrchové úpravy vstřikováním – DFM

Povrchová úprava vstřikováním podle klasifikačních systémů SPI a VDI – Lesklá, pololesklá, matná a strukturovaná povrchová úprava.Obsah tohoto článku Co jsou povrchové úpravy vstřikováním?Proč používat povrchové úpravy při vstřikování?Injekce...Přečtěte si více -

7 způsobů, jak snížit proces vstřikování

Existuje 7 způsobů, jak snížit náklady na vstřikování, včetně: Optimalizace designu: Dobře optimalizovaný design může pomoci snížit množství použitého materiálu a snížit složitost procesu formování, a tím snížit náklady na výrobu.Vyberte si správný materiál...Přečtěte si více -

Ultrazvukové svařování

Ultrazvukové svařování je proces spojování, který využívá vysokofrekvenční mechanické vibrace ke spojení dvou nebo více kusů materiálů dohromady.Tento proces se běžně používá ve výrobě ke spojování plastů a plastů, stejně jako jiných materiálů.Ultrazvukové svařování má několik...Přečtěte si více -

Jaký je vztah mezi plastovou vstřikovací formou a rychlostí smršťování?

Vztah mezi vstřikovací formou plastů a mírou smršťování je složitý a ovlivněný několika faktory, včetně: 1. Typ materiálu: Různé plasty mají různé míry smrštění, které se může pohybovat od 0,5 % do 2 %, což má významný dopad na rozměrovou přesnost a kvalita o...Přečtěte si více